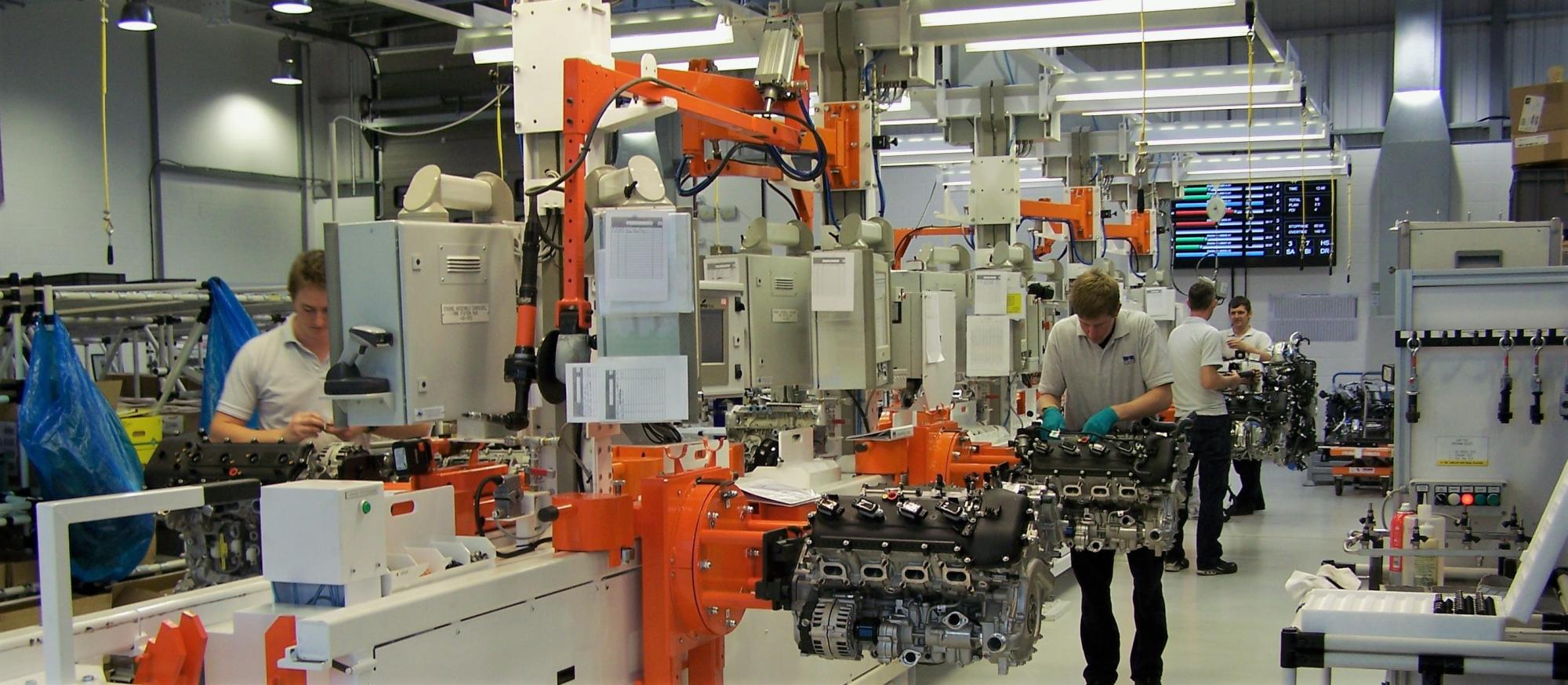

MacDonald Humfrey Automation and ExMac Automation collaborate to deliver Ricardo's 600m2 state-of-the-art assembly facility to build a new high-performance engine.

The facility at Ricardo’s Technical Centre in Shoreham, West Sussex was specified, designed, constructed and commissioned in less than 18 months by the MacDonald Humfrey Automation Group. Essential to the success of this project was ExMac Automation’s previous experience with ‘no fault forward’ (NFF) assembly on a similar engine build project for Harley-Davidson’s V-Rod engine. This proved invaluable to Ricardo which was manufacturing its first engine.

“From the start, ExMac understood our brief, asked the right questions and were able to provide relevant technical input and their own suggestions to help us achieve our objectives for the line", says Ricardo's Dave Thompson. "Because the space available in the assembly facility couldn’t accommodate a continuous loop system, designing the conveying system proved particularly challenging, as did the 50-minute total average cycle time (TACT), which was relatively slow due to the low production volume – eight engines per shift – and the demands of the comprehensive NFF culture. All of which also meant that a fully automated system wasn’t justified.”

The design of ExMac's handling system allowed Ricardo to load engine blocks onto the line and rotate them at any of the 10 assembly stations. The system was also indexed manually to allow greater control over the assembly process, provide the flexibility to accommodate long cycle times and enable Ricardo to achieve batch production of single engines or different engines as required.

To meet the specification within the space available ExMac designed a compact 10-station back-to-back manual line that takes up very little floor space in the new building. A FAT line was prebuilt at MHA's Luton plant to allow Ricardo engineers to test the line thoroughly ahead of its installation at Shoreham.

Commenting for Ricardo, Thompson praises the level of detail and thought behind how the line operates. "One of ExMac's innovations is a novel low-cost method of rotating the engine using a battery-operated electric drill fitted with a special socket that is attached to the gearbox that enables an engine to be positioned wherever it is needed" Thompson confirms that Ricardo is pleased with the end result Leidos ExMac's aesthetic approach to the design of the line ensured that it complements the new engine-build facility and presents an attractive and technically advanced visitor environment for Ricardo’s internationally renowned customers."

MacDonald Humfrey (MHA) created a bespoke HMI system for Ricardo drawing on its considerable experience and expertise in developing similar systems for Aston Martin, BMW and Jaguar Land Rover.

The HMI system created by MHA provides Ricardo production engineers with a list of operations they can vary and configure by themselves along with a set of ‘task-by-task’ instructions that show assembly operators how to build the engine, as well as the time allocated to each task, DC tooling operations, air tests and gasket glue plotting. The HMI also provides full integration of operations plus confirmation - with a time and date stamp – that all tasks have been completed.

The custom-built system provides engine line operators showed step-by-step guidance with detailed on-screen information and visual aids at each of the 10 stations, including instructions for every bolt to be tightened and its particular torque and angle.

Commenting on the success of the project, Paul Crosbie, Technical Director at MacDonald Humfrey Automation says, “The success of this collaboration with Ricardo is typical of what MHA and ExMac excel in. Mechanically, ExMac’s handling system is extremely robust and when combined with the sophistication of an MHA control system, is a prerequisite for reliability. The completed line has more than exceeded Ricardo’s overall performance expectations.”